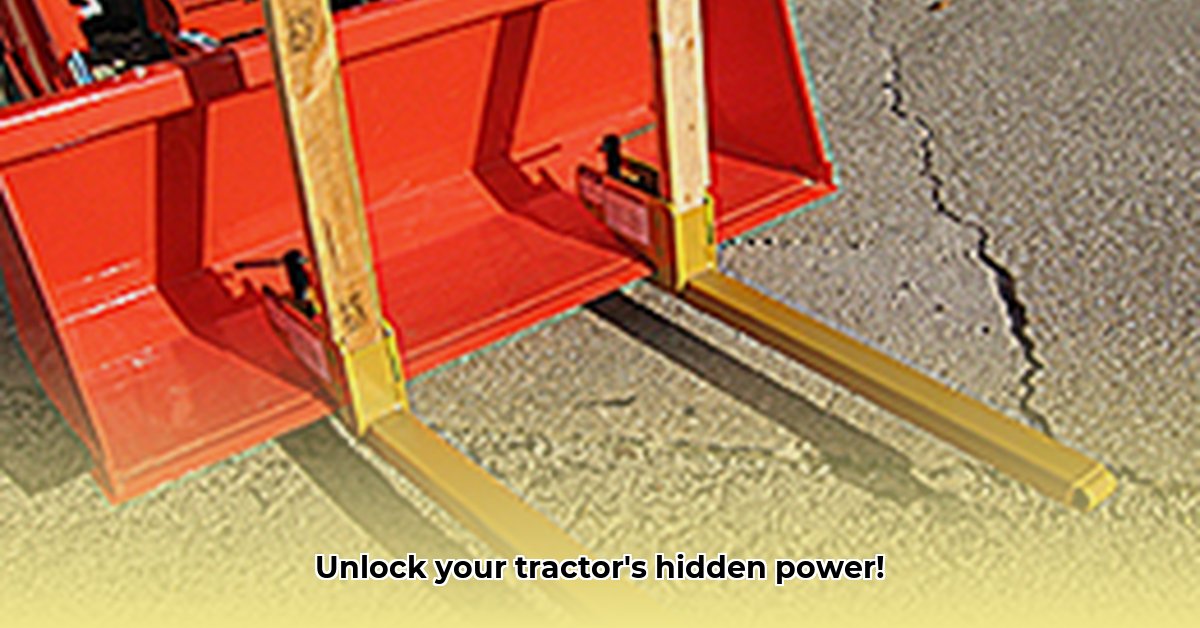

Clamp-on loader forks transform your tractor bucket into a versatile material handling powerhouse, boosting efficiency and saving you valuable time. This comprehensive guide covers selection, installation, safe operation, and maintenance, equipping you with the knowledge to maximize your tractor's potential. We'll also explore market trends and safety considerations to ensure you make informed decisions. For more information on specific tractor forks, check out John Deere Forks.

Understanding Clamp-On Loader Forks

Clamp-on loader forks are attachments designed to significantly enhance your tractor bucket's functionality. They enable more efficient lifting, carrying, and placement of various materials, from hay bales to construction debris. This increased versatility translates to time savings across a range of applications, benefiting farmers, landscapers, and construction workers alike. However, understanding the nuances of different fork types is crucial for optimal performance and safety.

Types of Clamp-On Loader Forks

Clamp-on loader forks come in various designs, each suited for specific tasks and tractor types. Key factors to consider include weight capacity, material composition, and design features.

- Weight Capacity: Ranges vary significantly, from around 1000 pounds to over 6000 pounds for heavy-duty models. Always ensure the fork's capacity aligns with your tractor's lifting capabilities.

- Materials: Most forks are constructed from robust steel, but high-strength alloys offer enhanced durability and longevity, especially for demanding applications.

- Design: "W" model forks, designed for enhanced stability, have gained popularity, particularly for use with compact loaders and buckets featuring bolt-on cutting edges.

Here's a summary of common fork types:

| Fork Type | Typical Weight Capacity (lbs) | Best Uses | Material | Considerations |

|---|---|---|---|---|

| Standard | 1000-6000+ | General material handling | Steel, High-Strength Alloys | Wide range of sizes and lengths available |

| "W" Model | Typically lower | Compact loaders with cutting edges | Steel | Optimized for compact loaders and enhanced stability |

| Heavy-Duty | 6000+ | Extremely heavy loads, pallet handling | High-Strength Alloys | Ideal for demanding applications and heavy materials |

Choosing the Right Forks: A Decision-Making Framework

Selecting the right clamp-on forks requires careful consideration of several factors. This decision-making framework will guide you through the process:

Define your needs: What materials will you primarily be handling? What are their typical weights?

Assess your tractor: Determine your tractor's lifting capacity. This is a critical safety measure; never exceed this limit.

Set your budget: Clamp-on forks offer a range of price points, reflecting variations in material, capacity, and features.

Prioritize safety: Look for forks with robust locking mechanisms, clearly marked weight limits, and good visibility of the load.

Consider "W" Models: For compact loaders, "W" model forks offer enhanced stability and compatibility. Could they be appropriate for your application?

Choosing the right forks involves careful analysis and balancing your needs with budget and safety concerns. Is it better to invest in a higher capacity fork that can handle a broader range of materials, or is a less-expensive fork suitable for your application?

Installing Your Clamp-On Forks: A Step-by-Step Guide

Correct installation is crucial for safety and optimal fork performance. Follow these steps meticulously:

Preparation: Ensure your tractor is turned off, parked securely on level ground, and the area is clear of obstructions.

Alignment: Carefully align the fork clamps with your bucket's lifting lugs. Precise alignment ensures a secure and stable fit.

Fastening: Use a torque wrench to tighten the clamping bolts to the manufacturer's specified torque. Overtightening can damage the clamps or the bucket.

Testing: Before lifting heavy loads, perform a test lift with a small, lightweight object to verify stability and proper installation. Inspect for any looseness or misalignment.

Final Check: Double-check all bolts to ensure they remain tightly secured before operating with your intended load. Remember, proper installation is a key safety measure.

Safe Operation and Maintenance: Ensuring Longevity and Safety

Safe operation and regular maintenance are essential for extending the lifespan of your forks and preventing accidents. Always:

- Inspect forks before each use: Check for cracks, bends, or loose fasteners.

- Never exceed weight capacity: Overloading can lead to structural failure and serious injury.

- Maintain visibility: Ensure a clear line of sight to the fork tips during operation.

Regular maintenance is also crucial. Clean debris after each use. Periodically lubricate moving parts to prevent wear, and check bolt tightness. Is it better to err on the side of caution and schedule more frequent inspections rather than less?

Market Overview & Future Trends

The demand for clamp-on loader forks is rising, driven by increasing needs in agriculture and construction. Several key trends are shaping the market:

- Standardization: Efforts are underway to standardize fork dimensions and mounting systems to enhance compatibility across different brands.

- Enhanced Safety: Manufacturers are incorporating improved safety features, such as enhanced locking mechanisms and clear weight indicators, into their designs.

- Material Advancements: The use of high-strength materials is becoming more prevalent, further increasing fork durability and longevity.

- "W" Model Popularity: The increasing popularity of compact loaders is fueling greater demand for "W" model forks which are optimized for these smaller machines.

These trends signal a future of more robust, safer, and versatile clamp-on loader forks, continuing to improve efficiency and productivity.

Conclusion: Prioritize Safety and Maximize Efficiency

Clamp-on loader forks offer a cost-effective solution for enhancing your tractor's versatility and efficiency. However, safe operation and regular maintenance are paramount. By selecting appropriate forks, following installation guidelines, and adopting safe operating practices, you can maximize the productivity of your tractor while minimizing risks. Remember to consult your owner's manual for specific instructions and seek professional assistance when needed. Prioritizing safety ensures both efficiency and peace of mind.

Resources

While specific manufacturer links are not available in the provided text, a valuable resource for finding reputable manufacturers and safety standards would be a search on sites like Tractor Supply, other farm supply companies, or directly searching for "clamp on loader forks" on sites like Amazon. Always check reviews and confirm safety ratings before purchasing.